Pinched Ultrasonic Sensors

All Tesla models currently have 12 ultrasonic sensors surrounding the car (6 in the front, 6 in the back) that helps the car with parking, autopilot, and many other features.

During the assembly process, these sensors could get pinched on the plastic bracket, which then causes them to be misaligned. This can pose a serious threat as if a sensor is not seated properly, the car may not have complete data about it's surroundings which could lead to accidents on the road.

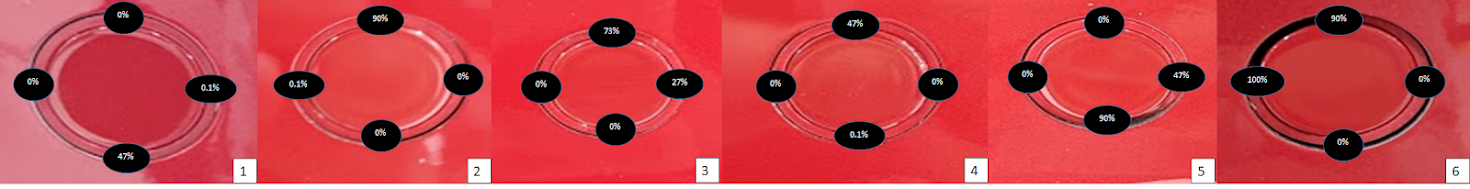

The image on the left shows what a pinched sensor is. The old solution to this problem was to have quality inspection operators disassemble the sensor, and reinstall it manually. This caused increased cycle times, as well as was a strenuous task for the operators. This problem was solved by reprogramming the robot assembly process, causing a higher throughput rate.

In an effort to maintain continous improvment, the pinched sensor problem had to be resolved. This was done by collecting data on which sensors were failing, and how often. The results from this showed that sensors closer to the edges of the fascia were failing most often. This was because the part sits on the skid with only the middle section of the fascia in contact with the skid. By doing this, the center of the fascia is secured, however the ends are not constrained. Therefore, the robot assembly places the sensor in the exact spot everytime, which may not be the center of the bracket.