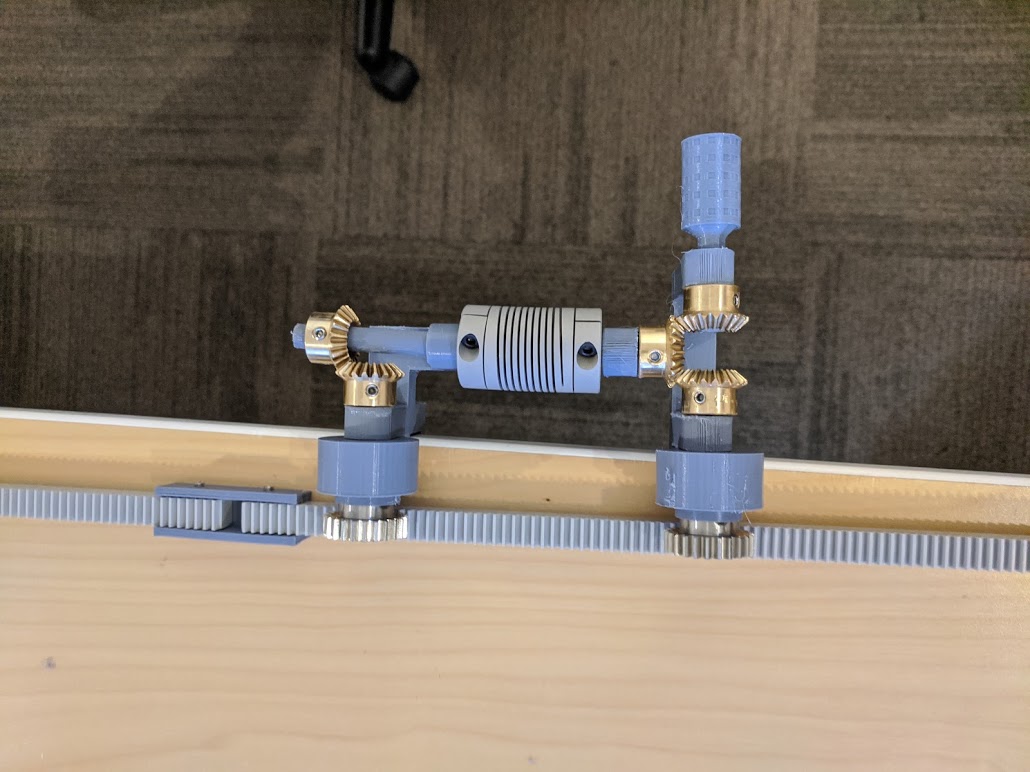

Open Differential Drivetrain

At Able Innovations, I was tasked with constructing the primary drivetrain that would drive a bed under a patient and transfer them across to another surface. Due to space constraints, this mechanism had to be extremely compact with many other requirements.

My chosen solution was to create an open differential drivetrain with linear shaft coupler used to allow linear compliance. The primary drive method used a rack & pinion seperated by gaps to allow for modularity. Because of this, the rack-to-rack gap may not be exactly the same throughout and therefore some amount linear compliance is needed to drive two seperate racks with the same motor.

The gif shown here illustrates the problem where the gap creates complications when driven.

To overcome this, linear compliance was implemented to allow for manufacturing tolerances as well as improve reliability of system.